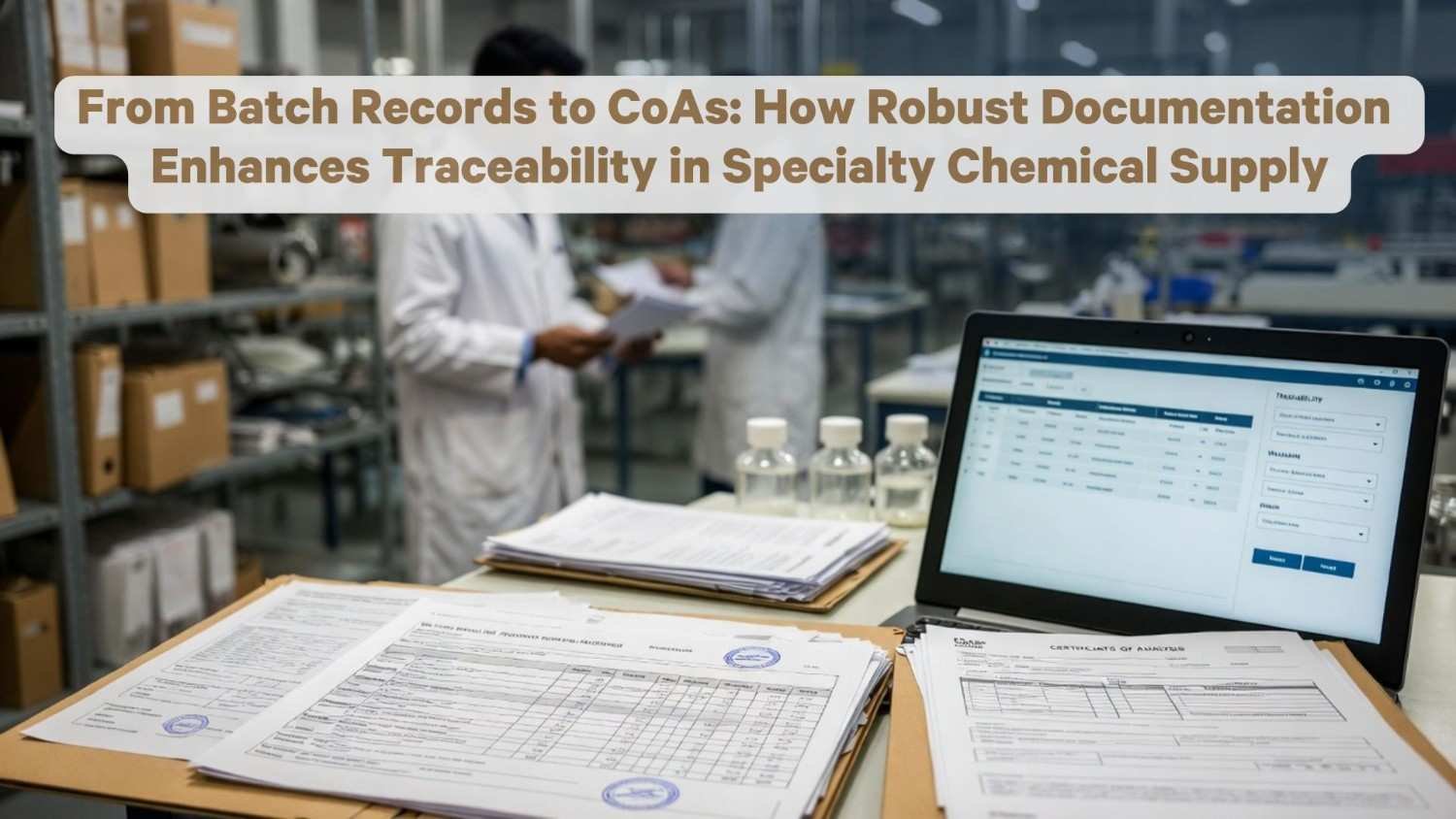

In today’s highly regulated and globally connected chemical industry, product quality alone is no longer enough. Buyers of specialty chemicals, especially pharmaceutical, diagnostic, and research laboratories, expect complete transparency, traceability, and accountability across the supply chain. At the center of this expectation lies robust documentation.

From detailed batch manufacturing records to Certificates of Analysis (CoAs), documentation is the backbone that connects raw materials to finished products. It not only ensures regulatory compliance but also builds trust, reduces risk, and enables long-term supplier relationships. This article explores how strong documentation practices enhance traceability and why they are essential in modern specialty chemical supply chains.

Why Traceability Matters More Than Ever?

Traceability refers to the ability to track a chemical product through every stage of its lifecycle, from sourcing raw materials to final delivery. In specialty chemicals, where products are often used in sensitive applications such as diagnostics, pharmaceuticals, and biotechnology, traceability is non-negotiable.

Global regulations, customer audits, and quality expectations have made traceability a core requirement rather than an optional feature. Any gap in documentation can lead to compliance failures, rejected batches, or loss of buyer confidence.

Batch Manufacturing Records: The Starting Point of Traceability

Batch manufacturing records are the foundation of traceability. They document every step involved in producing a specific batch, including raw material inputs, process parameters, equipment used, and in-process quality checks.

These records allow manufacturers to:

- Identify variations between batches

- Investigate deviations or complaints efficiently

- Demonstrate process control during audits

For buyers, batch records assure that the product was manufactured consistently and under controlled conditions. Even if batch records are not shared directly, their existence supports the credibility of downstream documentation such as CoAs.

Raw Material Traceability and Supplier Accountability

Traceability does not begin at manufacturing; it starts with raw material sourcing. Robust documentation links each batch of finished product to specific raw material lots, suppliers, and testing results.

This linkage is crucial in specialty chemicals, where impurities or inconsistencies in raw materials can significantly impact performance. When suppliers maintain detailed incoming material records, they can quickly trace and isolate issues if a problem arises.

For international buyers, this level of transparency reduces risk and simplifies regulatory compliance.

Process Documentation and Quality Control Logs

Beyond batch records, process documentation captures the real-time controls applied during manufacturing. This includes temperature ranges, reaction times, pH adjustments, filtration steps, and cleaning procedures.

Quality control logs complement this by recording analytical testing, acceptance criteria, and release decisions. Together, they demonstrate that quality is built into the process rather than inspected at the end.

Such documentation is especially important for specialty chemicals used in regulated labs, where consistency and reproducibility are critical.

Certificates of Analysis (CoAs): The Buyer’s Primary Reference

The Certificate of Analysis is often the most visible and most scrutinized document in the specialty chemical supply chain. It summarizes key quality attributes of a specific batch, including test results, specifications, and compliance statements.

A well-structured CoA enhances traceability by clearly linking:

- Product name and grade

- Batch or lot number

- Test methods and results

- Manufacturing and expiry dates

For buyers, the CoA is not just a formality; it is a decision-making tool. Clear, accurate, and consistent CoAs signal a supplier’s commitment to quality and transparency.

Linking CoAs Back to Batch and Process Data

True traceability is achieved when CoAs are not standalone documents but part of an integrated documentation system. Each CoA should be traceable back to batch records, raw material logs, and quality control data.

This linkage allows manufacturers to respond quickly to customer queries, audits, or regulatory inspections. It also enables efficient root-cause analysis in case of complaints or deviations.

From a buyer’s perspective, this integration reduces uncertainty and increases confidence in the supplier’s systems.

Regulatory Compliance Across Global Markets

Specialty chemical suppliers often serve customers across multiple regions, each with its own regulatory expectations. Robust documentation supports compliance with diverse frameworks such as GMP, ISO standards, and country-specific regulations.

Even when chemicals are not classified as pharmaceutical actives, downstream users may still require documentation aligned with regulated environments. Suppliers with strong documentation practices are better positioned to serve global markets without frequent rework or delays.

Risk Mitigation Through Documentation

Documentation plays a critical role in risk management. In the event of a quality issue, recall, or regulatory inquiry, traceable records allow suppliers to limit exposure by identifying affected batches quickly.

Without proper documentation, even minor issues can escalate into significant business disruptions. Conversely, suppliers with transparent records can demonstrate control and accountability, preserving both reputation and customer relationships.

Building Trust with Global Buyers

In international trade, buyers often evaluate suppliers remotely, without frequent site visits. In such cases, documentation becomes a proxy for trust.

Consistent batch records, professional CoAs, and complete technical documentation reassure buyers that the supplier operates with discipline and integrity. Over time, this trust translates into repeat orders, long-term contracts, and strategic partnerships.

Documentation as a Competitive Advantage

While many suppliers view documentation as a compliance obligation, forward-looking manufacturers recognize it as a competitive differentiator. Strong documentation systems enable faster onboarding of new customers, smoother audits, and greater market access.

For specialty chemical suppliers targeting regulated industries or foreign markets, documentation quality can be as important as product quality.

The Future of Traceability in Specialty Chemicals

As digital systems, data integrity requirements, and sustainability reporting gain prominence, documentation will continue to evolve. Buyers increasingly expect not only accurate records but also quick access, consistency, and alignment with digital workflows.

Suppliers who invest in robust documentation today are better prepared for future regulatory and market expectations.

Conclusion

From batch manufacturing records to Certificates of Analysis, documentation is the thread that ties together quality, compliance, and trust in specialty chemical supply chains. Robust, well-maintained records enhance traceability, reduce operational risk, and strengthen confidence among global buyers. By prioritizing structured documentation practices, suppliers such as GSP Chem demonstrate a disciplined approach to quality management that supports long-term partnerships.

In an industry where precision matters, documentation goes beyond paperwork; it becomes tangible evidence of reliability, accountability, and a commitment to consistently meeting high standards.