In every laboratory, whether it’s a pharmaceutical research center, a diagnostic testing facility, or an academic lab, precision is everything. A single inaccurate reading can alter results, delay breakthroughs, or compromise quality control. That’s why the reliability of pH indicators and reagents is not just a technical detail; it’s the foundation of every successful experiment.

So, here’s the big question:

Are your pH indicators and reagents reliable enough for your most sensitive lab applications?

In this article, we’ll explore why quality matters, what defines a reliable reagent, and how choosing the right supplier, such as GSP Chem, can ensure your laboratory maintains accuracy, consistency, and compliance across every process.

Why Reliability Matters in pH Indicators and Reagents?

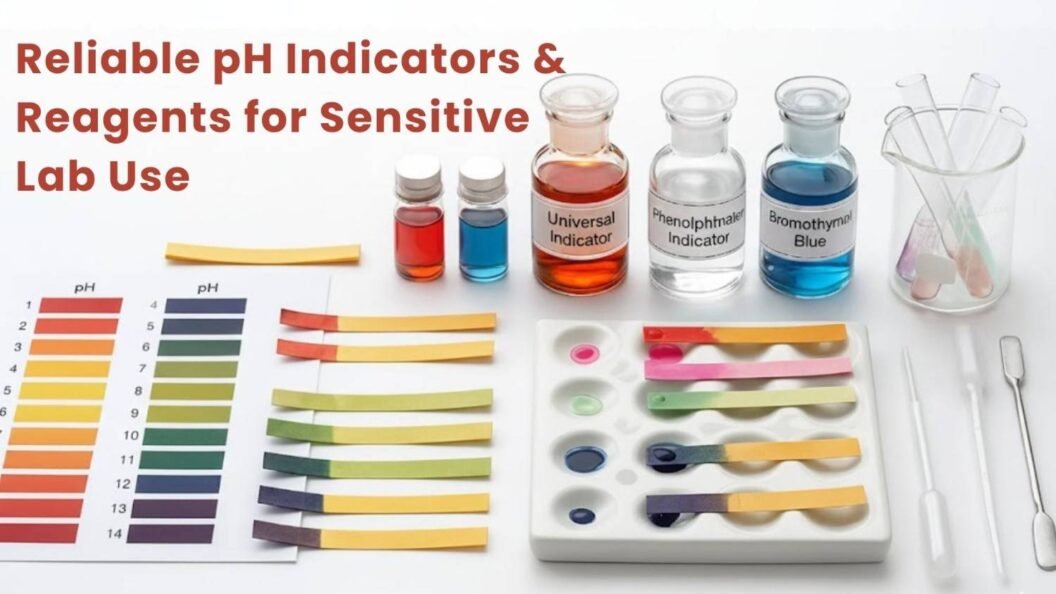

pH indicators and reagents are vital tools for chemical analysis, titrations, diagnostics, and environmental testing. Their main role is to provide precise, visible, and repeatable results based on chemical changes.

However, when these compounds are of poor quality, the consequences can be severe:

- Inconsistent color change during titration

- Fluctuating pH readings due to impurity interference

- Reduced reproducibility of experimental results

- Compromised quality assurance in regulated industries like pharmaceuticals and biotechnology

In sensitive environments, such as cell culture labs, water testing facilities, or clinical research centers, even the slightest variation in reagent quality can lead to incorrect conclusions or wasted resources.

That’s why leading scientists and chemical professionals always prioritize high-purity reagents and indicators for dependable results.

What Defines a Reliable pH Indicator?

A reliable pH indicator must do more than simply change color. It should perform consistently under a variety of controlled conditions without degradation or variability.

Key characteristics include:

a. High Purity

Impurities can alter the color transition point or absorbance spectra, leading to false readings. Reliable indicators like phenol red, bromocresol green, or thymolphthalein must meet stringent purity specifications (often ≥99%).

b. Accurate Transition Range

Each indicator has a defined pH range where color change occurs, for example:

- Methyl Orange: pH 3.1 – 4.4

- Phenol Red: pH 6.8 – 8.4

- Bromothymol Blue: pH 6.0 – 7.6

A dependable product maintains this transition range precisely, ensuring reproducible results.

c. Chemical Stability

High-quality indicators are resistant to light, temperature fluctuations, and oxidation, making them suitable for long-term use in critical research.

d. Batch-to-Batch Consistency

Reliable suppliers guarantee consistent performance from one production batch to another, a key factor for industries that rely on reproducible outcomes.

Understanding Laboratory Reagents and Their Reliability Factors

Laboratory reagents are the building blocks of every experiment. Their reliability defines the accuracy of your overall results. But what makes one reagent superior to another?

a. Purity Grade

Reagents are available in different grades, such as analytical, laboratory, and pharmaceutical. For sensitive applications, Analytical Reagent (AR) or ACS-grade materials are recommended.

b. Trace Impurity Control

Even minute contaminants like metal ions or organic residues can interfere with reactions. High-quality reagents are purified and tested for trace-level impurities.

c. Certification and Documentation

Reputable suppliers provide Certificates of Analysis (COA) and Material Safety Data Sheets (MSDS) for each product batch, ensuring traceability and regulatory compliance.

d. Storage and Shelf Life

Reliable reagents maintain stability over time when stored properly, protecting against degradation or contamination.

Common Issues from Unreliable Indicators and Reagents

Using substandard materials can silently undermine your entire workflow. Here are some real-world problems caused by poor-quality pH indicators and reagents:

- False Positives or Negatives – Inaccurate pH detection during titrations or biochemical testing.

- Contaminated Reactions – Impurities react with target compounds, skewing results.

- Reduced Product Yield – Especially in synthesis or pharmaceutical formulation.

- Failed Compliance Audits – In regulated sectors, where documentation and reproducibility are crucial.

- Higher Operational Costs – Repeating tests increases material and labor expenses.

The solution? Consistency, quality control, and sourcing from a trusted manufacturer.

The GSP Chem Standard: Precision, Purity, and Performance

At GSP Chem, quality isn’t a choice; it’s a commitment. As one of India’s trusted chemical reagent suppliers, the company has built its reputation on precision, reliability, and innovation.

Here’s how GSP Chem ensures the reliability of every indicator and reagent:

a. Stringent Quality Control

Every product batch undergoes multiple stages of chemical purity analysis, including spectrophotometric and chromatographic testing.

b. Compliance with International Standards

All reagents and indicators meet ISO and analytical-grade quality norms, ensuring compatibility with global laboratories and manufacturing facilities.

c. Certified Documentation

Each product is delivered with complete COA and MSDS documentation, providing transparency and traceability for audits and research validation.

d. Innovation in Chemical Formulation

GSP Chem continually invests in modern synthesis and purification techniques to enhance stability, purity, and environmental compliance.

e. Application-Specific Solutions

Whether it’s for pharmaceutical analysis, biotechnology research, or environmental testing, GSP Chem offers tailored products designed for sensitive and high-precision applications.

Best Practices for Ensuring Reagent Reliability in Your Lab

Even with the highest-quality chemicals, reliability also depends on how you store and handle them.

Follow these expert tips to maintain reagent integrity:

- Store indicators in tightly sealed, labeled containers away from direct light and humidity.

- Always use clean, dry instruments to avoid cross-contamination.

- Record the batch number and date of opening for traceability.

- Dispose of expired reagents according to chemical waste management guidelines.

- Regularly calibrate instruments that measure pH or absorbance to ensure accurate readings.

By combining quality products with disciplined lab practices, you can achieve unmatched consistency and confidence in your results.

Why Reliability Is the Future of Chemical Innovation?

As industries embrace automation, smart analytics, and sustainability, the demand for reliable reagents will continue to rise. Laboratories are moving toward zero-error systems, where AI-driven analytics and IoT sensors monitor every chemical reaction.

In this future, suppliers like GSP Chem play a key role in bridging innovation with reliability, delivering high-purity, eco-friendly indicators and reagents that perform flawlessly across global industries.

Conclusion

Your laboratory’s success depends on accuracy, and accuracy starts with reliability. Whether you’re measuring a delicate pH balance, running complex titrations, or performing diagnostic tests, using trustworthy pH indicators and reagents ensures your work stands up to the highest scientific and industrial standards.

With GSP Chem’s high-purity products, certified processes, and commitment to innovation, laboratories across the world can focus on discovery, not doubt.

So next time you ask, “Are my reagents reliable enough?”, make sure the answer is a confident yes with GSP Chem.